The machinery that we use is a major part of Australia’s mining industry, and its efficiency can often be neglected, especially when it comes to the wear and tear endured by fittings and custom nozzles. These components play a crucial role in mining machinery and the repercussions of neglecting their upkeep can be detrimental to operations and the contracted deliverable deadlines. This is why there is wisdom in partnering with a trusted supplier like Spraytech Systems so you can get the necessary parts replaced in a timely and efficient manner.

Understanding The Significance Of Fittings And Nozzles In Mining

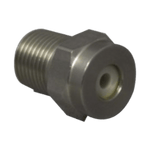

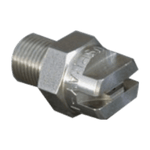

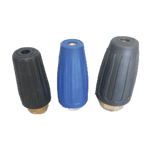

Fittings and nozzles are the unsung champions of the mining sector. This is because they are designed to perform a specific task efficiently as part of heavy machinery operating in some of the harshest and most challenging terrain in the world. These vital parts produce seamless mists and accurate dispersal of necessary fluids, such as industrial chemicals, fuels and water.

In the Kimberley region, one of the 9 mining regions in Western Australia, dust control is paramount due to environmental and worker safety requirements. Fittings and nozzles play a central role in dust suppression systems, reducing the potential for environmental harm and health risks associated with dust. They also ensure the efficient dispersion of reagents, a crucial step in the extraction of valuable minerals. Any deterioration or damage to these components can directly impede mineral recovery rates, thereby impacting your company’s profitability.

Additionally, mining machinery often confronts extreme temperatures in this region, necessitating precise cooling mechanisms. Fittings and nozzles contribute to machinery cooling systems, ensuring equipment remains within safe operating temperature ranges. Failure of a nozzle can result in costly machinery breakdowns and production interruptions, which the remote and challenging terrain of rural Western Australia exacerbates.

The Toll Of Neglected Wear And Tear

In an industry where profit margins are a wealth generator for infrastructure and mean the survival of regional towns and cities, the reliability and efficiency of machinery are of the utmost importance. Neglecting the wear and tear on fittings and nozzles can have grave consequences, both operationally and financially.

As these components deteriorate, they can disrupt fluid flow, leading to operational inefficiencies, contamination, leakages and the rusting of internal parts and electronics. The ripple effect often leads to increased operational costs. Malfunctioning fittings and nozzles can pose safety hazards such as leaks, spills, and uncontrolled fluid dispersion, endangering workers and the environment. These hazards can lead to regulatory penalties, legal liabilities, and reputational damage.

Moreover, machinery breakdowns arising from worn or damaged fittings and nozzles can result in significant downtime. This unanticipated halt in operations can disrupt production schedules and necessitate costly on-site repairs, which can be logistically challenging in Australia’s remote mining regions. When parts have to arrive via freight train, truck convoy or by air on a limited schedule, it often results in delays for you and your mining company.

To add, if your nozzles are often used for dust suppression, the orifice size can get larger as time goes on. Given that more of the dust suppression product is being sprayed, this may result in decreased efficiency and a less effective final product. Certain moisture content limits are permitted in some situations when the mined product is sold by weight, and conflicts from mining firms’ clients may occur when these tolerances have been exceeded.

Choosing A Trusted Supplier: Spraytech Systems

Selecting a reliable supplier for replacement fittings and nozzles is a strategic choice for the success of mining operations everywhere. Spraytech Systems is a trusted name in the industry, equipped with knowledge about industrial machinery parts and the average wear-and-tear. In addition to their top-tier products, they provide exceptional technical customer support. Their team offers invaluable guidance and assistance, assisting mining companies in making informed decisions regarding replacement parts suitable for specific machinery and their applications.

Your mining company can ensure the longevity of its machinery, improve productivity, and fulfil contractual obligations while adhering to safety and environmental responsibility in these demanding and environmentally sensitive regions by implementing a proactive maintenance approach and collaborating with reputable suppliers like Spraytech Systems.

Get in touch today to order your regular replacements and find out more about your fittings and nozzles before they cost you dearly.