Overview

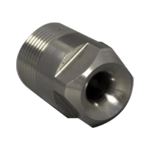

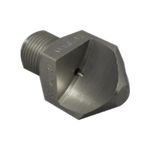

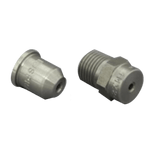

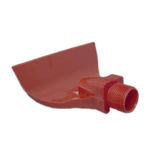

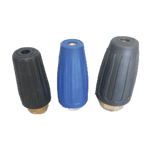

About Spraytech’s Axial Hollow Cone Nozzles:

An Axial Hollow Cone Nozzle features spiral grooves along its axis, and under pressure these cause a rotary motion in the liquid that produces atomisation. The resulting spray is extremely fine, with very small droplets that are uniform in size and which are distributed in an even, cone spray pattern.

The fine, atomised spray produced by an axial hollow cone nozzle means that uniform coverage across a greater surface area can be achieved. This is particularly helpful in applications where rapid evaporation is required, or when there needs to be an even distribution of a liquid across an entire surface.

The cone spray pattern achieved with an axial hollow cone nozzle also means there is less spray drift, increasing efficiency and minimising waste.

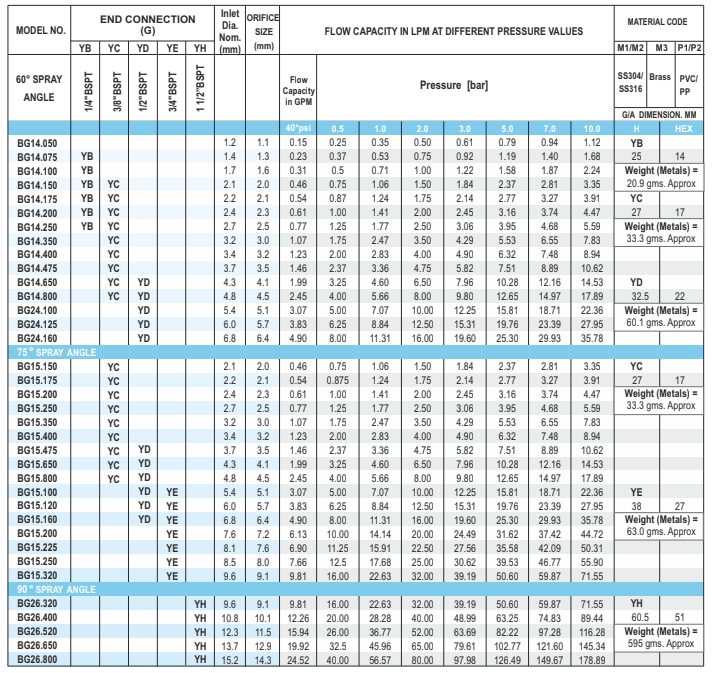

At Spraytech Systems, we supply a range of Axial Hollow Cone Nozzles with different thread sizes, spray angles, capacities and operating pressures:

- Thread sizes BSP(M): ⅜″, ½″ and ¾

- Spray angle: 50˚ to 80˚

- Capacity (litres per minute): 0.64 to 44.4

- Pressure (bar): 0.5 to 6.0